Did you know that the Water Resources Act affects your cooling lubricant system?

Many companies use cooling lubricant emulsions (KSS) – but not all of them know that these substances must be classified according to water hazard classes (WGK) and that handling them is subject to strict requirements under German water legislation.

The general requirements of the Water Resources Act (WHG) are specified in the AwSV (Ordinance on Installations for Handling Substances Hazardous to Water).

Even individual tanks with a volume of less than 220 l can be AwSV-relevant – but the actual topic only really becomes relevant with automation.

Automation is not a risk – if it is done right:

Manual filling processes are usually observed directly – employees recognize overfilling immediately.

Automated systems, on the other hand, run unattended – and this is precisely why the AwSV requires technical safeguards such as overfill protection, leakage detection and retention devices for such systems.

This is no reason to worry – but a reason to rely on well thought-out systems.

The good news:

There are solutions that not only fulfill these requirements, but also implement them in a practical and reliable manner – first and foremost Brisco Systems GmbH:

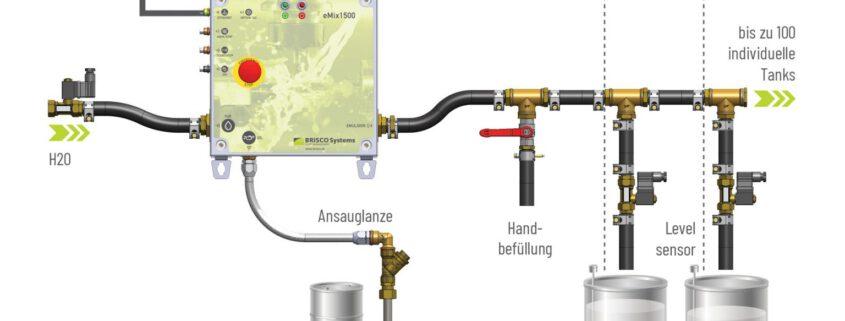

With the eMix1500 in combination with the eLevel100, a system is available that:

- via a fixed cable connection,

- an integrated level sensor,

- and an automatic emergency stop system

and thus technically rules out overfilling.

Are you planning to fill your cooling lubricant tanks automatically?

We have been dealing with the requirements of the Water Resources Act and the AwSV for many years. As a system integrator and official sales partner of Brisco Systems in Germany, GIMAT Liquid Monitoring advises companies on the planning and design of AwSV-compliant systems.

Feel free to contact us – you are in the best hands with us.