We are actively shaping the future of cooling lubricant management – with our hybrid approach

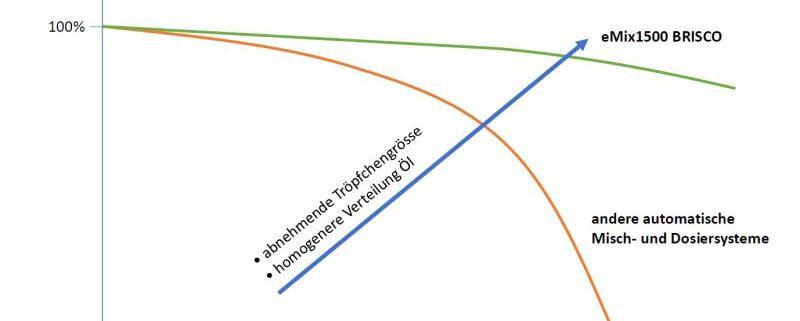

In modern production, efficiency is crucial in coolant management, among other things. At GIMAT, we have developed a forward-looking approach: Hybrid automation in cooling lubricant fluid management. We are pioneers of this concept. Wikipedia already describes our approach as the most economical way for small and medium-sized companies to manage cooling lubricant fluids – an endorsement that we are very pleased about.

To consolidate our leading role in this area, we have registered our “hybridPioneers” claim as a trademark with the German Patent and Trademark Office.

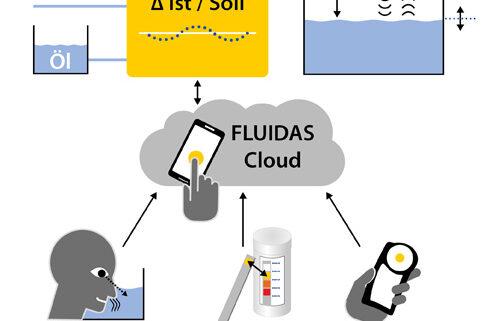

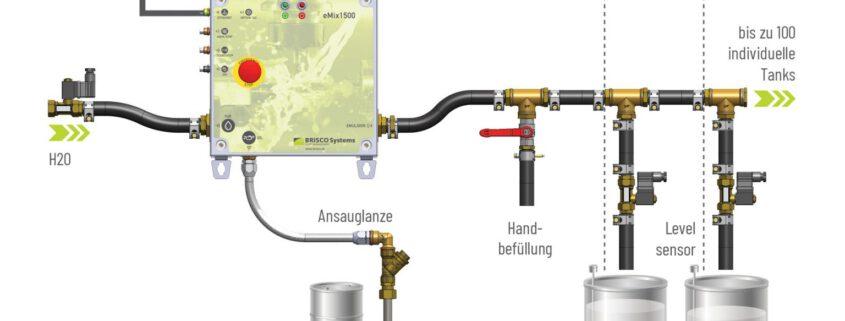

GIMAT is also a co-developer of DOSIMETRIX, the integrated solution for coolant supply. With our many years of expertise in measurement technology and as a certified ATAGO Service Center, we offer you sound and reliable solutions from a single source. We work closely with Brisco Systems GmbH (hardware solutions) and SDNORD (with the powerful FLUIDAS software), bringing hybrid solutions such as the DOSIMETRIX to the market.

Special thanks to Lars Löhner from FLUIDAS and Jürgen Gosch from Brisco and their teams for their excellent cooperation and valuable contribution to this project!