Cooling lubricants: Automatically achieve the perfect coolant emulsion with smartFusion technology

Mixing water and oil to create a stable cooling lubricant emulsion is a critical step in metalworking. Many companies have been using Venturi or proportional mixers for years – but the concentration has to be set manually.

However, modern fluid management demands more:

- Automatic setting of the target concentrations

- Optimal droplet size

- Homogeneous oil distribution

- Real-time control and system integration

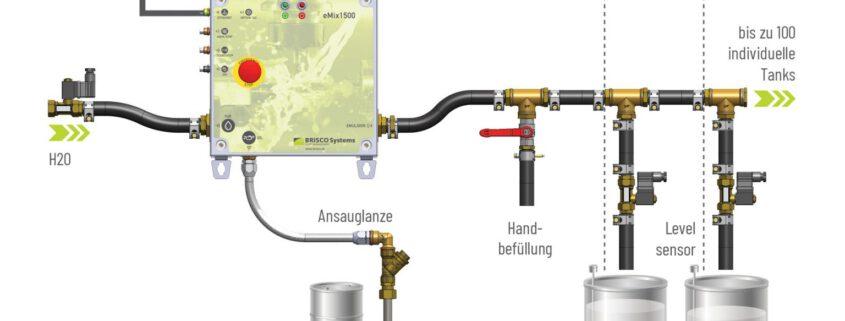

However, conventional technology cannot be used in mixing devices with automatically regulated cooling lubricant concentration. Brisco Systems, the Swiss developer and manufacturer of smartFusion technology and the eMix1500, has consistently implemented the high requirements for automatic mixing and is thus setting new standards:

- Almost perfect emulsion formation with very high dispersion quality

- Long-term stability without segregation

- Precise concentration control in real time

- Integration in hybrid or fully automated

- Fluid management solutions

The perfect emulsion is now created automatically.

The eMix1500 is the new reference for intelligent coolant mixing.

GIMAT is an official sales partner of Brisco Systems in Germany and brings this technology directly into your production.